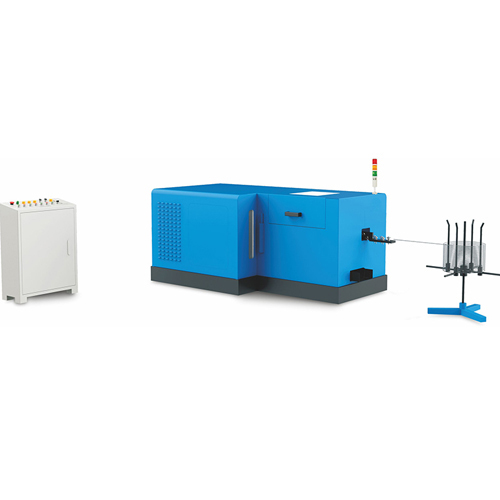

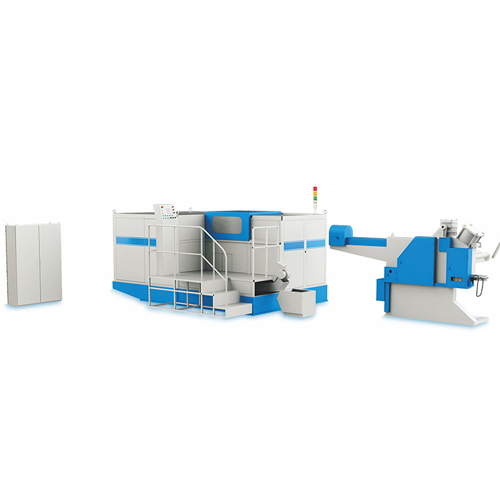

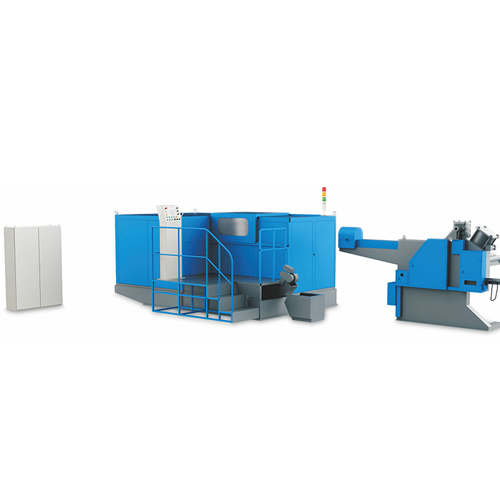

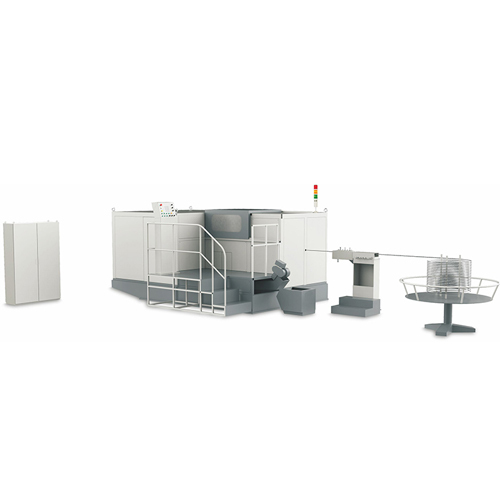

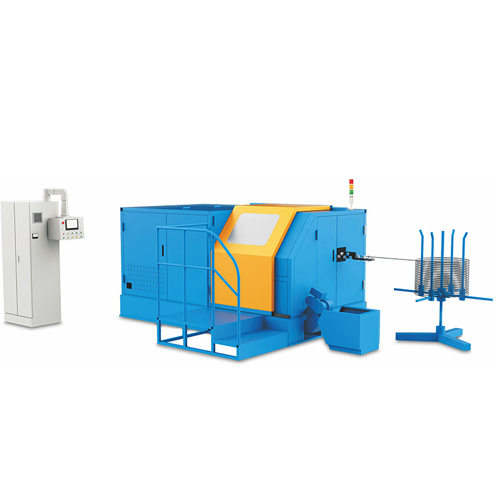

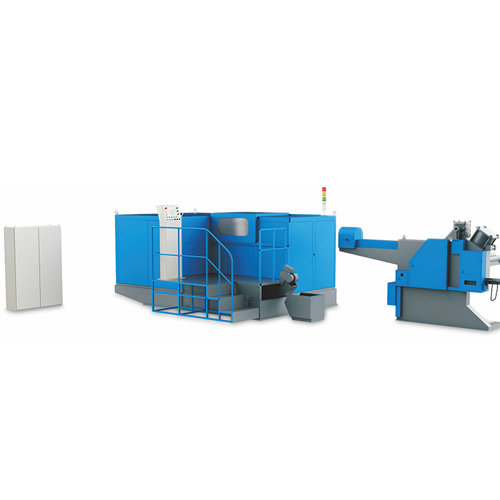

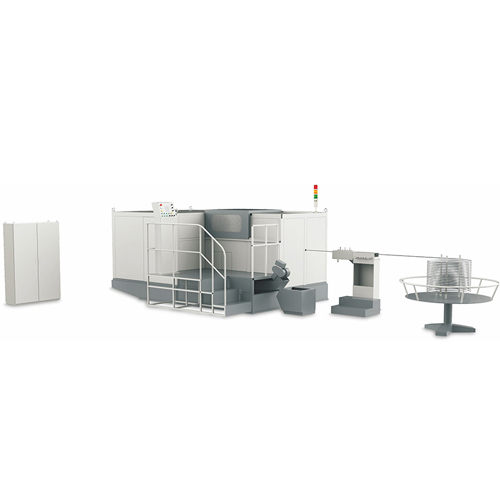

KD-520 5-MOLD 5-PUNCH High Speed precision Cold Heading Forming Machine Max cut dia. 25mm cut length 260mm

Product Details:

- Product Type Milling Machine

- Technology CNC

- Power Source Electricity

- Operating Type Automatic

- Pressure 380000 kgf/m2

- Surface Treatment Other

- Dimension (L*W*H) 13650*5500*3100 Millimeter (mm)

- Click to View more

KD-520 5-MOLD 5-PUNCH High Speed precision Cold Heading Forming Machine Max cut dia. 25mm cut length 260mm Price And Quantity

- 189999 USD ($)/Set

- 1 Set

- 189999.00 - 209999.00 USD ($)/Set

KD-520 5-MOLD 5-PUNCH High Speed precision Cold Heading Forming Machine Max cut dia. 25mm cut length 260mm Product Specifications

- CNC

- white

- 12 months

- Other

- Automatic

- Electricity

- 13650*5500*3100 Millimeter (mm)

- 80 Pcs/min

- 85000 Kilograms (kg)

- 380000 kgf/m2

- Milling Machine

KD-520 5-MOLD 5-PUNCH High Speed precision Cold Heading Forming Machine Max cut dia. 25mm cut length 260mm Trade Information

- Telegraphic Transfer (T/T)

- 500 Set Per Month

- 30 Days

- Asia Middle East

- All India

- CE

Product Description

Salient Features

-

Adopt air-pressure clutch imported from Italy and multi-frequency inverter imported from France, which can precisely control inching, inching and linkage of the machine. When stopping operation, the main sliding platform automatically stops at the last position to maximize the debugging space and make the adjustment more convenient.

-

Pneumatic rotary clamping mechanism is designed, which can adjust the clamping force arbitrarily, so that the machine can produce stably and at high speed. The first position clamp is equipped with short material monitoring device. When short material occurs, the clamp opens automatically and the clamp stops and the trichrome light warns.

-

The feeding and pressing pulleys are all controlled by electronic cylinder. The pressure of feeding and pressing pulleys can be adjusted at any time. They are separated automatically when returning. They are equipped with one-way bearings, linear feeding, etc. To prevent ratchet from reversing and feeding equally and stably.

-

The side-shaft cam-type shearing design can make the shearing speed fast and the shearing force great. The material cross section is smooth and smooth when the circumferential scissors are used.

-

The digitized post-levering mechanism can realize independent adjustment of recording length at each station, and the trimming cam can be installed at the last station to realize the trimming work. The front material retaining device can be installed under the main die, which is more stable in the production of short multi-step products.

-

Cam type male mold ejection control design, the ejection length of each male mold can be adjusted independently, and the adjustment is simple and fast, with higher accuracy.

-

The body, main sliding table, connecting arm and other key components are made of high-strength and high-toughness materials, and advanced casting forging technology and precise inspection process control are adopted to ensure high-speed and stable production of the machine.

-

The bearings are imported from NSK of Japan, SKF of Sweden and INA of Germany. The crankshaft and cam are made of high-strength wear-resistant alloy, and are subject to process treatment such as quenching and tempering, nitriding and heat treatment. Ensure the accuracy and service life of the machine.

-

The electric control system is equipped with multi-frequency inverter imported from France. Stepless variable speed can be realized in the production process. The PLC CNC detection system automatically monitors the real-time working state of the machine and prompts it by trichrome lamp in case of abnormality.

-

The machine operating system is independently developed and equipped with Siemens display control panel, which is easy and fast to operate.