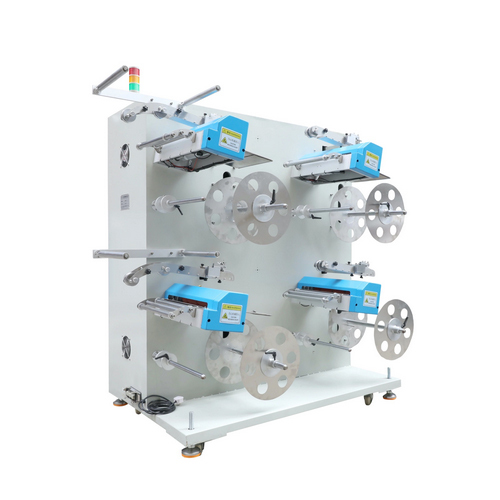

S Loop Straightener

उत्पाद विवरण:

मूल्य और मात्रा

- 1

व्यापार सूचना

उत्पाद वर्णन

1. S Loop high-speed straightener machine is a necessary advice to achieve synchronization with the press machine, it can control the delivery speed by inverter, material pass the buffer loop into the punch machine, it can control the machine condition stop or run or speed up, slow down, to achieve synchronization with the punching machine by commanding photoelectric switch.

2. This type of straightener machine is upgraded from the S loop straightener, specifically designed for high-precision thin material products, it is well known that the volume is not flat and stress relief cannot produce a good product, so the performance of the leveling machine plays a key role in production.

3. The leveling wheel is manufactured using imported SUJ2, heat-treated HRC60, rear grinding, and then hard chrome grinding to ensure uniform and shape tolerances for each shaft.

4. The leveling adjustment of this machine uses a floating four-point balance fine-tuning device, which can quickly find the leveling point.

5. The full machine uses high-precision bearings to extend service life.

6. Due to the material, material width and thickness are different, there is no unified numerical reference. So, it is recommended that take a small section of material to try before mass production, When it achieves the effect, then can started continuing production.

7. This machine sets transmission gear outside the body; it is convenient for oil lubrication and benefit to the operator's safety and effective protection.

(The price of the website platform is not the actual quotation, please contact us for the specific quotation according to your products and suitable machine models)

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+